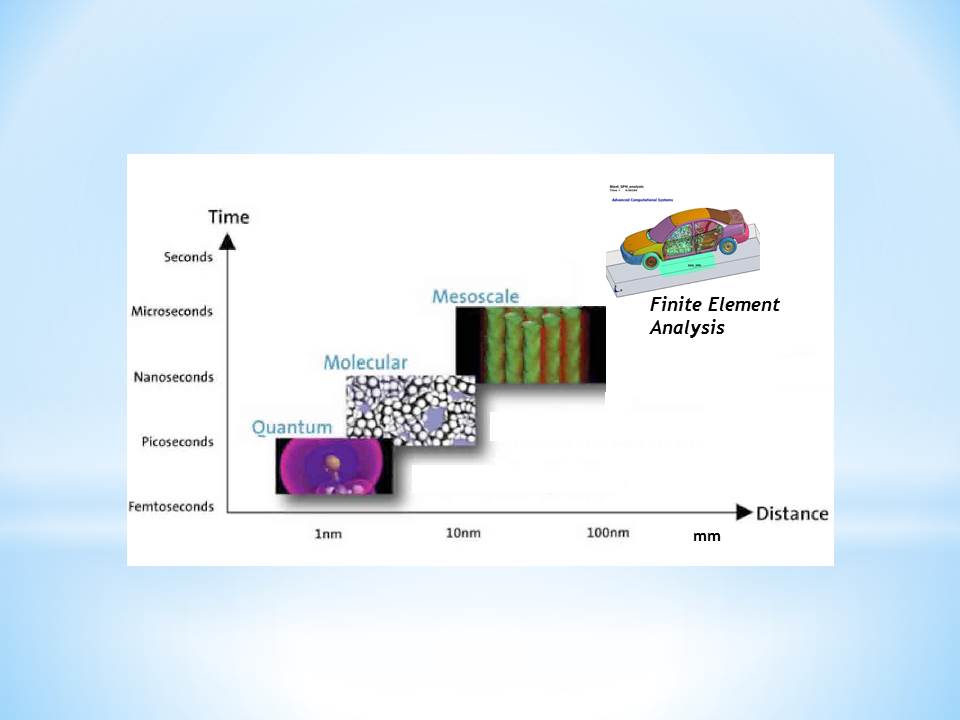

Product development in today's aerospace, automotive, defense industry is highly complex,expensive and time consuming.

Exponential growth in computer hardware technology in recent years is facilitating discovery and innovation through

Simulation based engineering and science. Simulation based design and analysis by integrating material science,

advanced manufacturing process from molecular dynamics to finished product macro models and optimization of the products

are the key factors in future product development. Integrated Computational Materials Engineering (ICME) combines

multiple models and system analysis tools.

Product development in today's aerospace, automotive, defense industry is highly complex,expensive and time consuming.

Exponential growth in computer hardware technology in recent years is facilitating discovery and innovation through

Simulation based engineering and science. Simulation based design and analysis by integrating material science,

advanced manufacturing process from molecular dynamics to finished product macro models and optimization of the products

are the key factors in future product development. Integrated Computational Materials Engineering (ICME) combines

multiple models and system analysis tools.

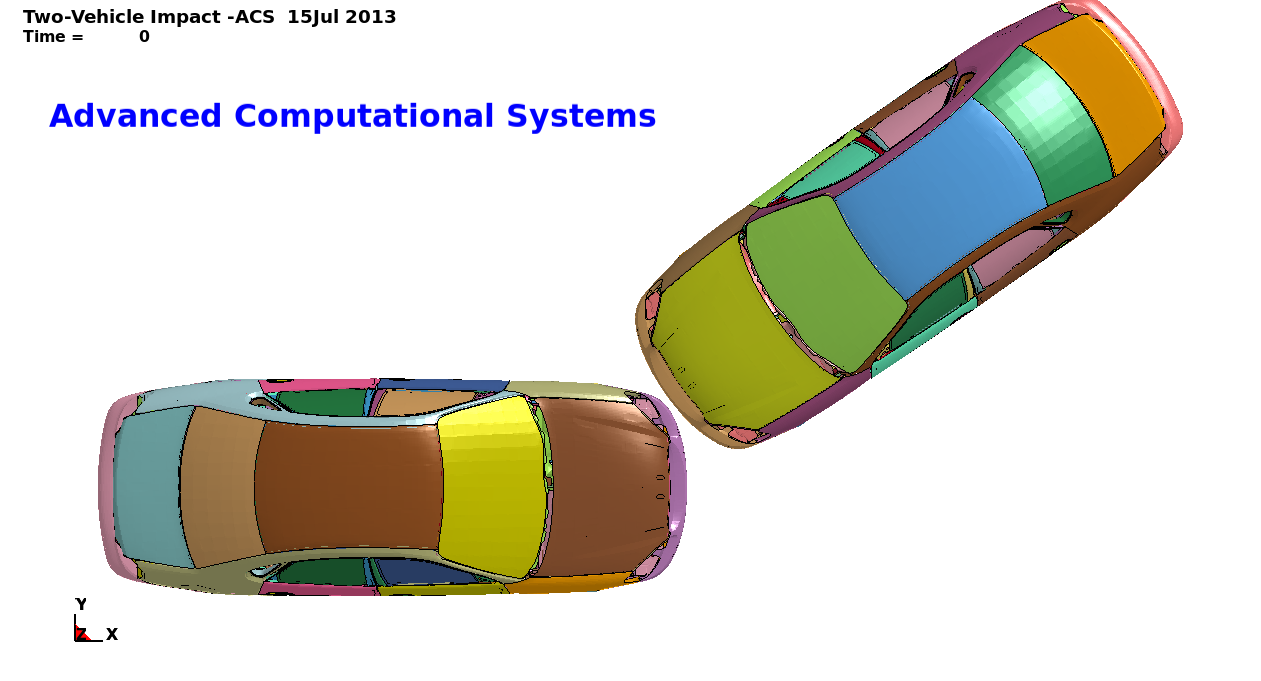

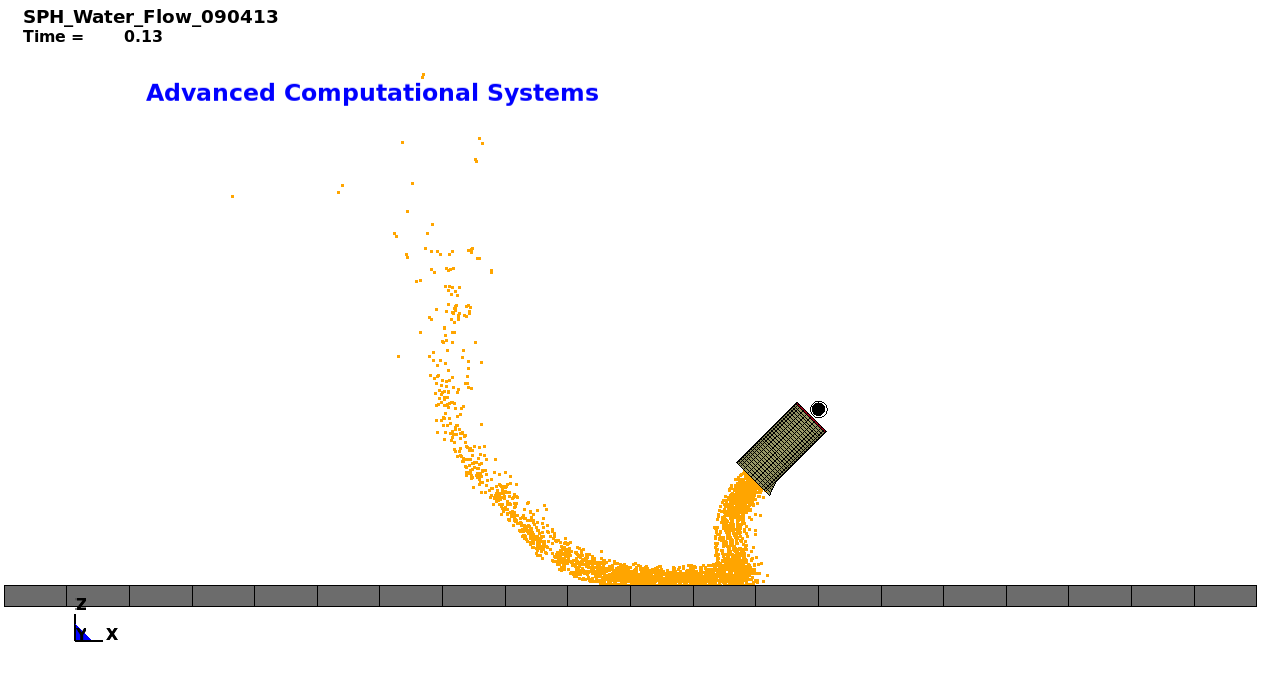

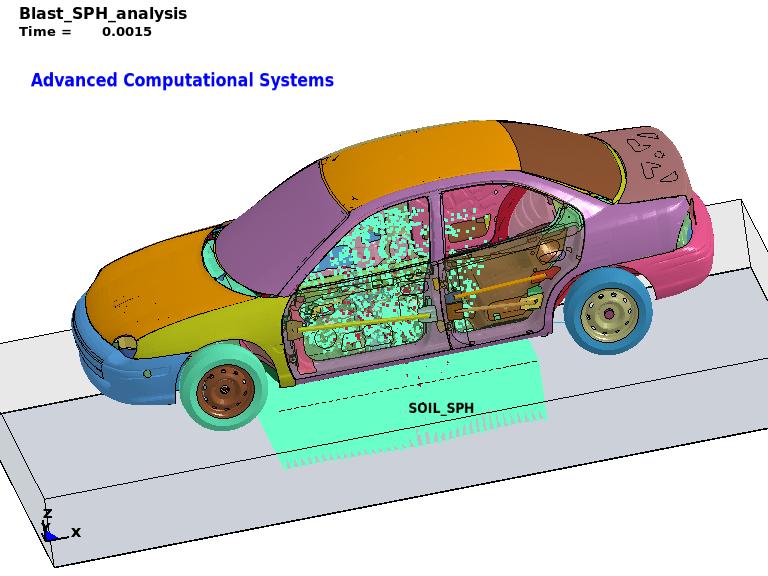

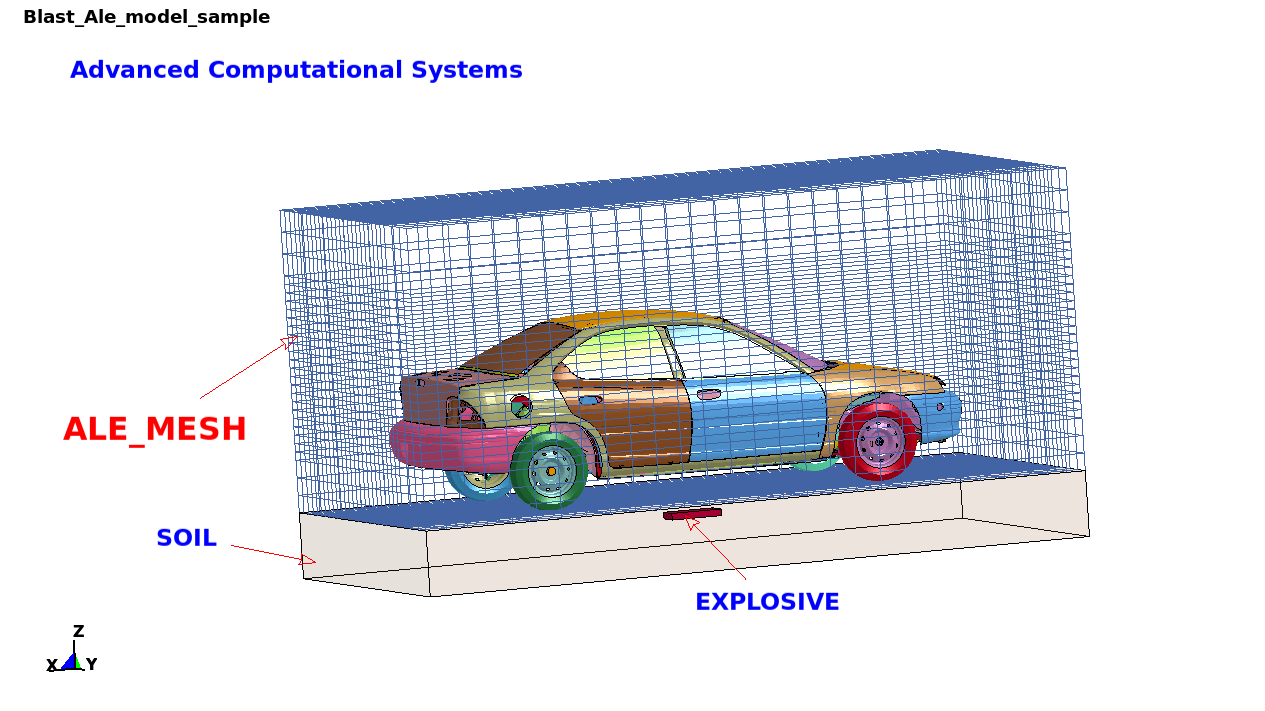

There is a paradigm shift taking place due to maturity of commercial engineering analysis tools such as ABAQUS, LS-DYNA,

NASTRAN, ANSYS, FLUENT, STAR-CD, PAM-FLOW, etc. LS-DYNA package provided by LSTC

has many modules which can be used for structural impact analysis, metal forming, multiphysics modeling for thermal,

electromagnetics, shock, explosion and fluid flow analysis. The solid fluid interaction simulation can be achieved by

using Arbitrary Lagrangian and Eulerian (ALE) technique and meshless SPH method. In addition, LSTC also provides optimization

module LSOPT for optimization.

There is a paradigm shift taking place due to maturity of commercial engineering analysis tools such as ABAQUS, LS-DYNA,

NASTRAN, ANSYS, FLUENT, STAR-CD, PAM-FLOW, etc. LS-DYNA package provided by LSTC

has many modules which can be used for structural impact analysis, metal forming, multiphysics modeling for thermal,

electromagnetics, shock, explosion and fluid flow analysis. The solid fluid interaction simulation can be achieved by

using Arbitrary Lagrangian and Eulerian (ALE) technique and meshless SPH method. In addition, LSTC also provides optimization

module LSOPT for optimization.

The vision of Advanced Computational Systems is to provide state of the art simulation technological solution by invoking some of ICME principles and developing material models in order to achieve faster product development.